Kaytex Sampeng is a family owned and operated business specializing in textiles manufacturing and conversion with three generations of experience. Whether our customer is seeking to reduce costs without compromising quality, to increase quality without losing profitability, or to create a unique product altogether, Kaytex is ready to provide the best possible solution. We have strong exclusive partnerships with some of the best spinning, weaving and dyeing factories in Thailand, and are able to tailor our production to fulfill our customers every requirement. We also have partnerships with garment manufacturers of the highest calibre, who offer superior workmanship in producing finished textiles products for export all over the globe.

Kaytex Sampeng is a family owned and operated business specializing in textiles manufacturing and conversion with three generations of experience. Whether our customer is seeking to reduce costs without compromising quality, to increase quality without losing profitability, or to create a unique product altogether, Kaytex is ready to provide the best possible solution. We have strong exclusive partnerships with some of the best spinning, weaving and dyeing factories in Thailand, and are able to tailor our production to fulfill our customers every requirement. We also have partnerships with garment manufacturers of the highest calibre, who offer superior workmanship in producing finished textiles products for export all over the globe.

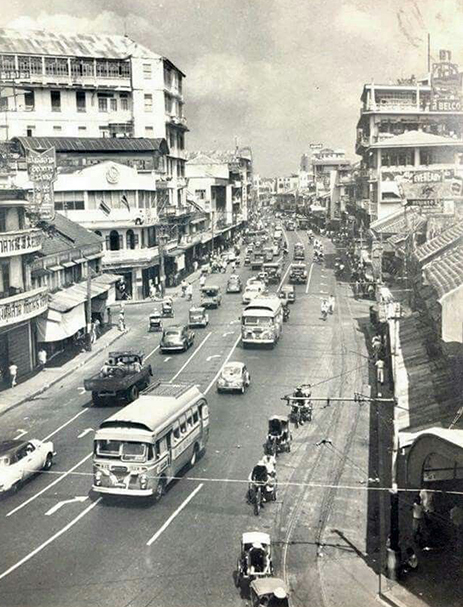

Kaytex has its roots firmly planted in Sampeng, Thailand’s textiles market, since the 1950s when our forefathers first started their trading operations. Over the years, the family business expanded from simple retail to large scale manufacturing of fabric, supplying Thailand’s garment industry during the Economic Boom of the 1980s.

One market, which has been a constant pillar in our business throughout the years, is the monks robes industry. Since 1986 we have designed and produced fabrics of every quality for Thailand’s largest manufacturers of monk’s garments, who supply robes and accessories to temples, and monk’s supply stores that sell these items to buyers, who would then donate them to the almost 400,000 Buddhist monks living all over the country (plus many more in surrounding nations as well). The foundation of this industry is built upon goodwill and earning merit through virtuous action, values which Kaytex strives to uphold in its dealings with all clients.

Owing to growing worldwide concerns over the well-being of our home, Planet Earth, Kaytex has recently ventured into the production of biodegradable plastics. After partnering with a well-established bio-plastics factory in Thailand, we are on the road to promoting a cleaner, greener and more sustainable future. Currently every roll of fabric that bears our logo is wrapped using biodegradable film, which decomposes within only 5 years time, compared to the usual 500 years taken by conventional plastic films. Our decision to switch to biodegradable packaging has resulted in thousands of kilograms of plastic waste being saved from choking the environment. With our bio-plastics division, we hope to provide environmentally conscious businesses the opportunity to contribute to a healthier future for our children and grandchildren in the years to come.

We as a company, strive our uttermost to give our clients the best possible products, at the best possible price, with the best possible service.

We strive to push the boundaries of what has been done in the past to create new products that can better serve our clients needs.

We strive to give our clients the best value for money for every product we produce in every price range.

We strive to fullfill our clients’ every need and give them the best customer service. We also strive to streamline our production and delivery process most efficiently in order to meet clients timelines.